Twin Shaft Mixer

Product Details:

- Weight 10000 Kilograms (kg)

- Usage industrial

- Size 4200*2300*2600

- Material Other

- Click to View more

Twin Shaft Mixer Price

- 600000 INR/Piece

Twin Shaft Mixer Specification

- 4200*2300*2600

- 10000 Kilograms (kg)

- Other

- industrial

Product Description

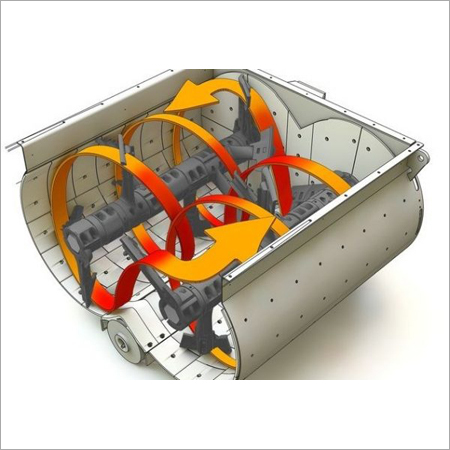

Twin Shaft Mixers are featured with the high-quality mixing blades and can work really well even in the opposite direction. These allow for excellent cross mixing and ensure a good mixing. The close clearance of these construction mixers make reduction of solids. Twin Shaft Mixers have high mixing speeds and allow for good bottom opening design. These are accessible with sanitary design-heavy gauge and can avoid contamination. We give them in a vast ambit of arability.

A twin shaft mixer is a type of concrete mixer used in the construction industry for efficiently mixing concrete and other materials. It is characterized by its two parallel mixing shafts that rotate in opposite directions, ensuring thorough and homogeneous mixing of aggregates, cement, water, and additives.

Specification of Twin Shaft Mixers:

- Fundamental specialized boundaries of JS1000 Concrete blender

- Appraised releasing volume 1000 L

- Evaluated taking care of volume 1600 L

- Appraised efficiency greater than equal 50 m3/h

- Force of blending engine 2x18.5 KW

- Force of winch engine 18.5 KW

- Force of water siphon engine 5.5 kW.

- Force of electrical oil siphon engine 0.06 KW

- Releasing stature 3800 mm

- The greatest molecule size of total 80/60(pebble/broken stone) mm

- Outer measurement (LxWxH) transportation state 4200x2300x2600 mm

- Outside measurement (LxWxH)Working state 9600x3700x10300 mm

- Weight of the entire machine 10000 kg.

FAQs of Twin Shaft Mixer:

Q: What Is a Twin Shaft Mixer?

A twin shaft mixer is a type of concrete mixer that features two horizontally mounted shafts with mixing arms that rotate in opposite directions to achieve efficient and uniform mixing of concrete ingredients.

Q: How Does a Twin Shaft Mixer Work?

In a twin shaft mixer, the mixing arms on the two shafts move through the mixing chamber, lifting and turning the concrete ingredients to ensure thorough blending and homogeneity.

Q: What Are the Advantages of Using a Twin Shaft Mixer?

Twin shaft mixers offer advantages such as fast and efficient mixing, consistent and high-quality concrete production, reduced mixing time, and the ability to handle a wide range of mix designs.

Q: Where Are Twin Shaft Mixers Used?

Twin shaft mixers are used in various construction projects, including ready-mix concrete plants, large-scale concrete production, precast concrete manufacturing, and infrastructure projects.

Q: Can Twin Shaft Mixers Handle Different Types of Concrete Mixes?

Yes, twin shaft mixers can handle a variety of concrete mixes, including standard concrete, high-strength concrete, self-compacting concrete, and specialty mixes.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free